Fleet-Lift Drop Forged Erection Anchor

Chontan Fleet-Lift Drop Forged Erection Anchor from China has been specifically engineered to provide better lifting capacity for horizontal-to-vertical edge lifts. The lateral supports in the anchor's head keep the ensuing forces from acting directly on the concrete during installation.

Send Inquiry

Product Description

What is Lift Drop Forged Erection Anchor?

To tilt and edge up precast concrete panels, erection anchors are always combined with premium steel. The bottom hole of the anchor is specifically made to accommodate the tension bar. The tension bar's end should be facing downward as you thread it through the bottom hole. Attach the tension bar firmly to the hole's bottom side. Deep within the precast concrete, tension bars distribute the stress caused by the lifting operation.

Fleet-Lift Drop Forged Erection Anchor SPECIFICATION

|

Load Group |

Axial Load |

Code |

Dimensions (Inch) |

||

|

Tons |

LBS |

L |

W |

T |

|

|

2.5 |

6000 |

R13-2.5 |

8 |

2 |

3/8 |

|

5 |

12000 |

R13-5.0 |

10-3/8 |

2-1/2 |

5/8 |

|

10 |

20000 |

R13-10.0 |

12-3/4 |

3-3/4 |

3/4 |

* Safety Factor is 4:1.

* Surface Black(B) /Zinc Plate (Z.P) / Hot Dipping Galvanizing (H.D.G) are available.

Product Display:

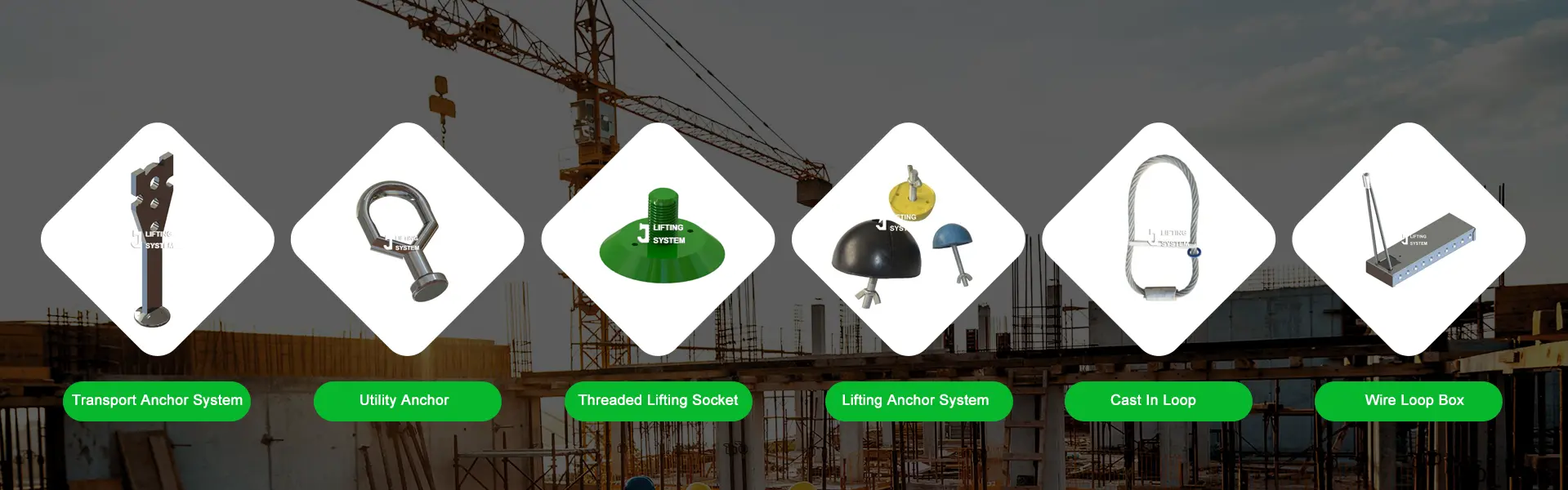

Erection anchors are built for lifting, transporting, and handling precast elements and slabs. A unilateral erection anchor lifts the element in a direction and provides the option of tilting the panel from a horizontal to a vertical position.

Application:

When arranging, it is important to keep in mind that the flat hanging nails have varied bearing capacities within and outside of the plane. The flat hanging nails are not only frequently used in typical prefabricated components but are also excellent for lifting the wall panels of the lifting system. The supporting hoist's spinning pin's end can fit through the string. The rope can be unhooked without requiring high-altitude labor, significantly lowering the risk to safety.