Straight Rebar Anchor

The Chontan straight rebar anchor supplied by China is designed for use in very thin walls,in the webs of reinforced concrete girders or precast garages. The anchor uses the same formers and lifting clutches as the normal lifting pin anchors while yet maintaining the same head size. The anchor may also be used to lift prefabricated masonry panels.

Send Inquiry

Product Description

The Chontan Straight Rebar Anchor is a cost-effective solution for anchoring steel reinforcement bars in concrete. It is made of galvanized steel and can be used as an anchor bolt in concrete foundations, walls, columns, corbels and beams. Straight Rebar Anchors are easy to install and provide superior holding power when compared to traditional anchors. They can also be customized to meet any specific application requirements. Straight Rebar Anchors are an excellent choice for projects that require strong reinforcement due to its simple design and reliable performance. Straight Rebar Anchors provide secure anchoring for a variety of applications, including concrete foundations, walls, columns and beams.

SPECIFICATIONS

|

Rated Load |

Code |

Popular Length |

Size (mm) |

|||

|

Tons |

L (mm) |

D |

D1 |

|||

|

2.5 |

400 |

520 |

|

14 |

26 |

|

|

4.0 |

L06-040 |

510 |

720 |

1150 |

18 |

36 |

|

5.0 |

L06-050 |

580 |

900 |

|

20 |

36 |

|

7.5 |

L06-075 |

750 |

1150 |

|

24 |

46 |

|

10.0 |

L06-100 |

870 |

1300 |

|

28 |

46 |

|

15.0 |

L06-150 |

1080 |

1550 |

|

34 |

69 |

* Other different Length are available according to the order.

* Safety Factor is 3:1.

* Surface Black /Zinc Plate (Z.P) / Hot Dipping Galvanizing (H.D.G) are available.

The Straight Rebar Anchor Feature:

The Chontan Straight Rebar Anchor is designed to increase the anchorage value of concrete without adding additional reinforcement. It can be used in precast and cast-in-place construction as well as post-tensioning systems. Straight Rebar Anchors are also suitable for use in any application requiring an anchor solution that requires minimal installation time, effort, and cost. Straight Rebar Anchors can be used in applications requiring an increase in the anchorage value of concrete without adding additional reinforcement. Straight Rebar Anchors are available in two standard sizes to provide a net bearing area of 4 or 9 times equal to the cross-section area of the bar. Straight Rebar is designed for use in precast and cast-in-place construction as well as post-tensioning systems. Straight Rebar Anchors are a convenient alternative to hooks in congested areas, with their secure and reliable anchorage performance.

How we produce?

We have 20 years of experience making lifting systems for precast concrete. Unlike other manufacturers, we invented our first semi-automatic forging process that produces these anchors faster and more efficiently. Everything is made in-house.

How it is used?

We work with you throughout the entire process, from initial design and planning to fabrication and installation. We understand that every project is unique, and we are dedicated to providing our clients with the personalized attention and support they need to ensure it is completed successfully. Contact us for details!

What’s your project?

After 20 years of just focusing in this industry, we have developed quite a full range of products for precast factories and their steel workshops, from all the 9 major types of precast lifting anchors and connection anchors, concrete reinforcement.

+ What types of products do we manufacture?

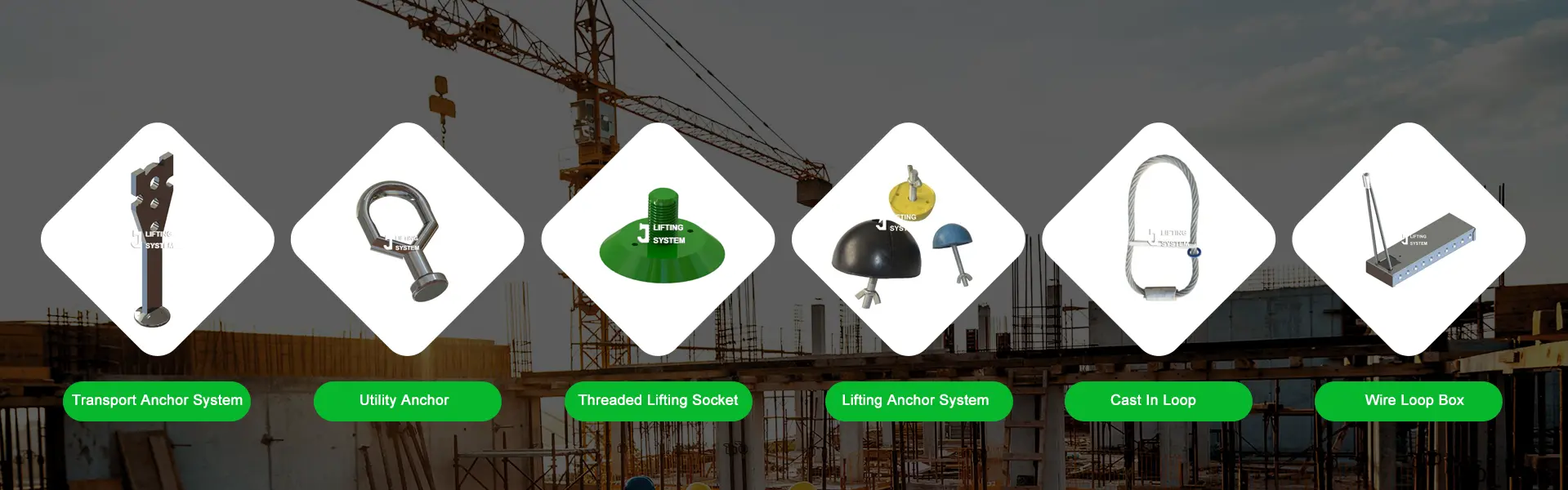

We do produce the complete range of all types of

Precast lifting anchors,

-- Lifting anchors, lifting eye anchors, off-set lifting anchors, lifting clutches, recess former;

-- Two-hole anchors, erection anchors, spread anchors, sandwich panel anchors, ring clutches, etc;

Threaded lifting sockets,

-- Lifting socket, wavy tail anchor, straight tail anchor, crown foot anchor, flat plate socket, bolt anchor socket, lifting loop, swivel lifting eye, etc.

Connecting systems

-- Cast-in channel, sandwich panel anchor, anchor pins, wire loop box, fiberglass connector pin, etc.

Fixing & Supporting,

-- Fixing socket, bended fixing socket, fixing insert with cross pin, etc.

+ What are the benefits of using lifting and connecting systems for the precast and prestressed concrete products?

Precast and prestressed concrete products offer many benefits, including reduced construction time, increased safety, superior strength, and improve durability. Lifting system possibility of establishing a connection in a safe, simple manner. The system consists of a wide range of sockets and a selection of accessories to allow most types of lifting applications.

ISO9001 and Intertek, CE marked, and products have been certified by TUV,SGS.

ERP and Digital management manage to every production process, Fully equipped labs for both mechanical & chemical properties.

Package & Delivery